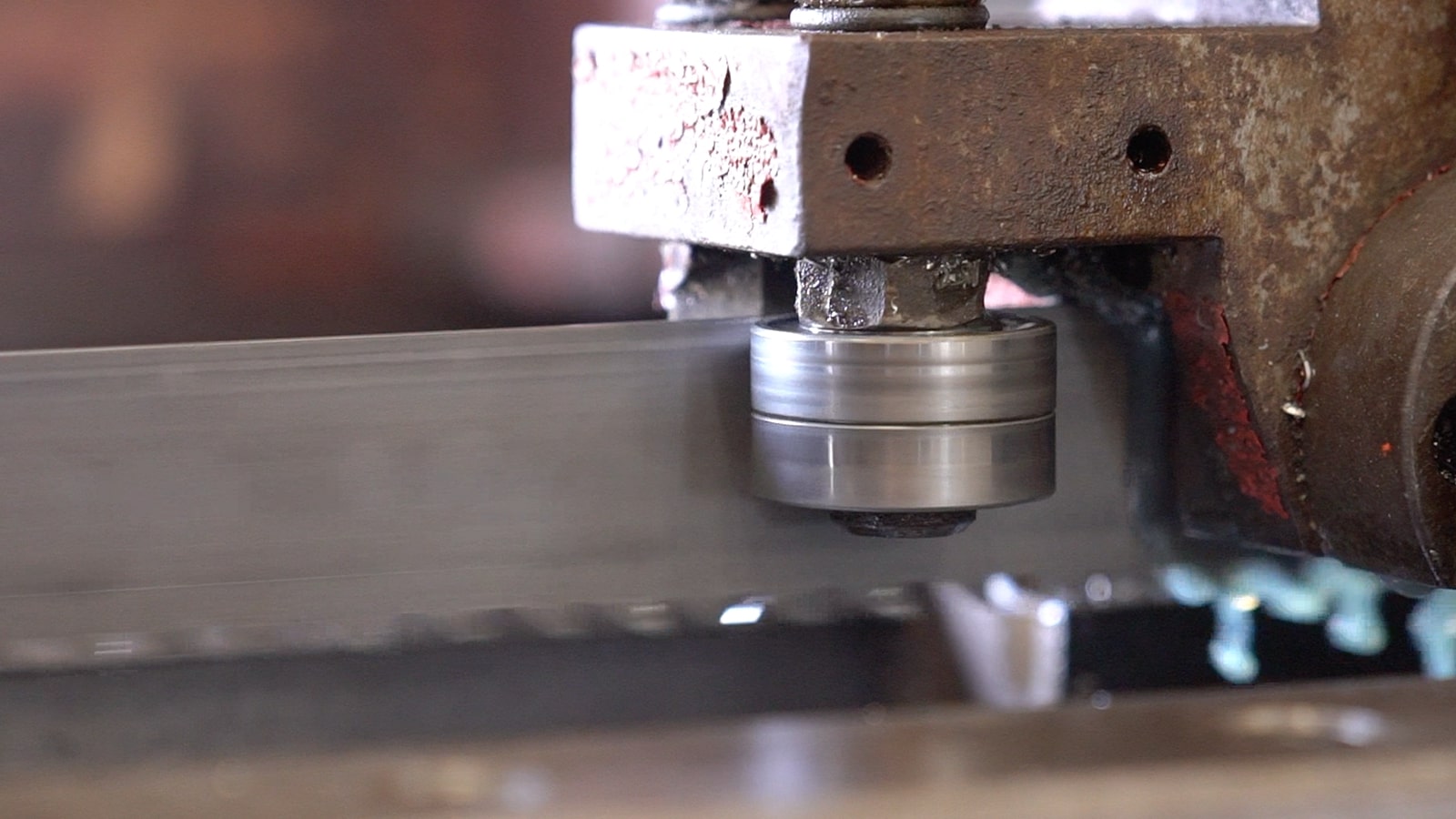

Back cracking is a progressive failure that can permanently damage a bandsaw blade and often signals mechanical or setup-related issues within the cutting system. While heavy use plays a role, most back cracks occur due to incorrect alignment, improper guide spacing, excessive tension, or running conditions that place stress on the back of the blade.

Guide arms that are spread too wide, worn or missing guides, incorrect guide-to-wheel alignment, or the blade rubbing the wheel flange can all lead to cracking over time. Speed, feed pressure, coolant performance, and run duration also play a significant role in whether a blade remains stable or begins to fail.

By monitoring the variables below and making minor corrections early, you can significantly reduce the risk of back cracks and extend your blade's life and stability.

Most Common Causes of Back Cracking

These are the most frequently observed contributors when blades begin cracking along the back edge:

1) Guide arms set too far apart

2) Incorrect guide-to-wheel alignment

3) Top guide missing

4) Blade rubbing the wheel flange

5) Notch worn into the top guide

6) Guides too tight

7) Straightness of the band compromised

8) Blade speed set too fast

9) Saw run for excessive duration

10) Tension too high

11) Feed rate too heavy

12) Feed pressure too high

13) Coolant flow too low

14) Coolant mixture incorrect

Proper alignment, spacing, coolant management, and operating adjustments are the most effective defense against back cracking. Identifying these conditions early helps maintain cut quality and prevents premature blade failure.

If you need troubleshooting assistance, contact Sawblade.com at 800-754-6920. Our experienced support team is ready to help.