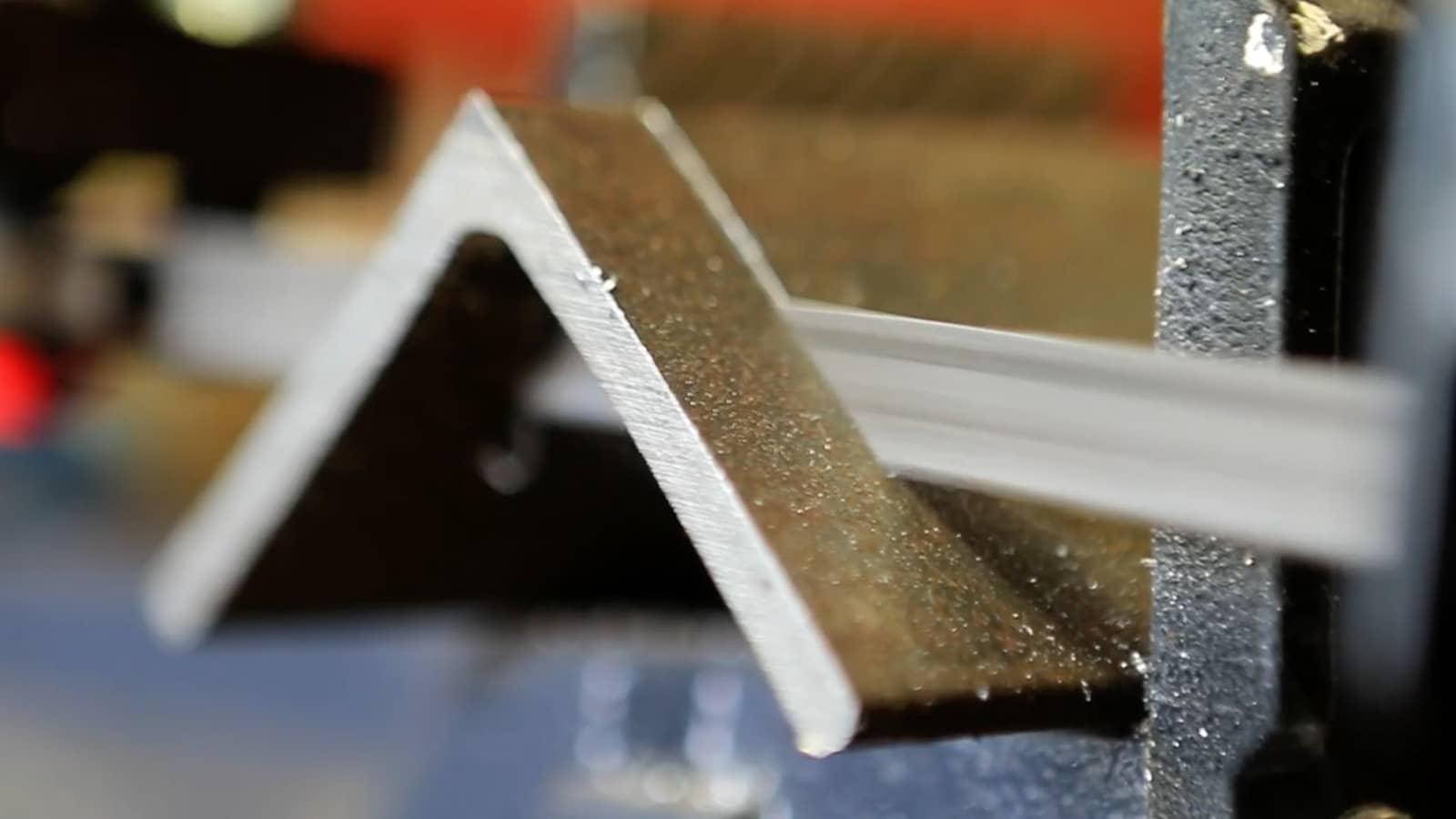

Weld Breakage in Band Saw Blades

Weld failure is one of the most disruptive and costly problems encountered when sawing. While it’s often assumed to be a manufacturing defect, many weld failures actually stem from machine setup, blade handling, and cutting conditions rather than the weld itself. With the right adjustments, most cases of weld breakage can be prevented.

If you’re experiencing repeated weld separation, reviewing system tension, wheel size, blade tracking, and guide condition is a great place to start. Below is a clear breakdown of the most common causes, presented in a streamlined format to help you diagnose issues quickly and keep blades operating safely and efficiently.

Primary Causes of Weld Failure & What They Mean

Tension Too High

Excessive blade tension places extreme stress on the weld area, leading to early failure.

Wheel Diameter Too Small

A tight radius forces the blade to flex beyond its tolerance, often causing cracks at the weld.

Blade Contacting Wheel Flange

Any rubbing or tracking misalignment increases heat and friction, weakening the welded joint.

Worn or Frozen Guides

Guides that don’t move freely or supply correct support can twist the blade and stress the weld.

Feed Rate Too Aggressive

Over-feeding the blade drives force into the weld faster than the material can be cut.

Chips Packed Into Guides

Poor chip removal leads to binding, heat buildup, and weld fatigue under load.

Feed System Out of Adjustment

Inconsistent or erratic feed pressure creates shock loading, a direct contributor to weld separation.

Internal Stress in Material

A pinched or shifting workpiece can snap the blade at its weakest point—the weld.

If weld breakage continues or you’d like help troubleshooting your setup, call Sawblade.com at 800-745-6920. Our support team is available during regular Central Time business hours and ready to assist.