Choosing the right blade tooth style is just as important as selecting the correct TPI. Different tooth geometries are designed to cut various metals more efficiently, improve blade life, control chip formation, and determine whether the cut is aggressive or smooth. Selecting the proper style ensures consistency, longer blade performance, and a finish that matches your expectations.

Sawblade.com offers several tooth configurations for metal-cutting bandsaw blades, each designed for specific applications:

Raker, HP, IC, and VTH tooth styles are the most common for metal. Understanding the differences among rake angle, chip flow, and cut aggressiveness makes it easier to select the correct blade for steel, stainless, alloy, tool metals, or structural materials.

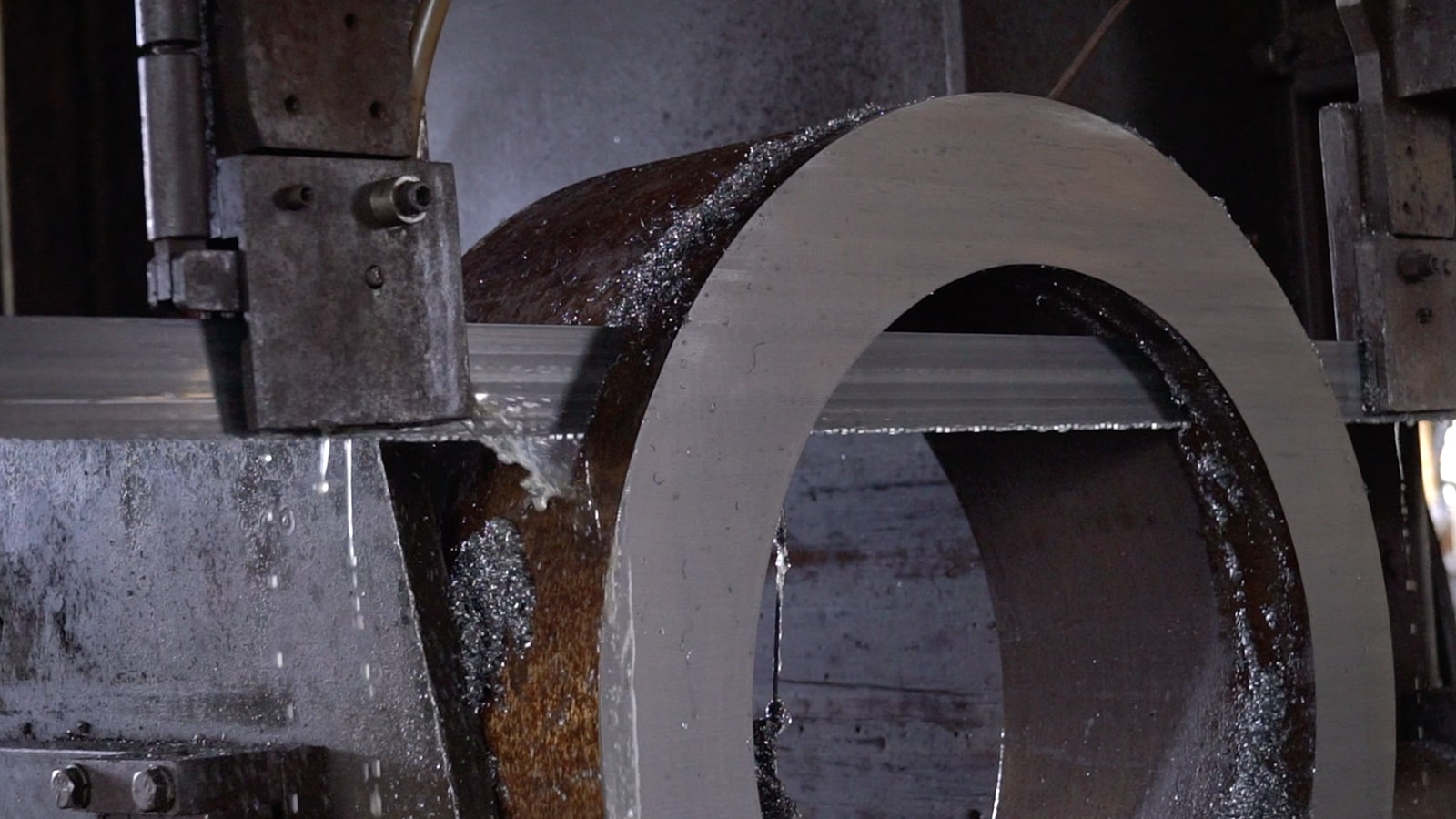

The video below explains these tooth forms in detail and helps you determine which is best for your sawing application.

Which Tooth Style Should You Choose?

1) Raker Tooth Style

Available in higher TPI counts and designed to produce a smooth, refined surface finish. Ideal for thin metals or precision cutting where finish quality matters most.

2) HP Tooth (High Penetration)

Features an aggressive geometry with an approximate 10° rake angle. Excellent for hard steels, alloy metals, and applications requiring fast feed and high metal removal rates.

3) IC Tooth (Intermediate Cutting)

Uses a moderate 7° rake angle, offering a balance of penetration and control. An excellent choice for structural steel or general shop use when a smoother cut is desired without sacrificing cutting speed.

4) 0° Rake Universal Tooth

A neutral cutting angle suited for everyday sawing tasks. Reliable, versatile, and ideal for operators who need a single blade that performs well across multiple metal types.

5) VTH Style

Designed for variable tooth height engagement, promoting smoother chip evacuation and reduced vibration — especially beneficial for tubing, pipe, or mixed-wall material cutting.

Watch the video above to see how each geometry performs and learn which blade style best matches your metal cutting requirements.

If you have any questions about selecting the proper tooth style for your metal cutting application, call Sawblade.com at 800-754-6920. Our experienced customer service team is always ready to help you choose the correct blade for your machine and material.